This season, we have another style using seamsealing in the garment. This style need more attention due to seamtape is need to be even due to avoid leakake issue. furthermore we need to prepare some points below :

- after we get the fabric from supplier, we need to do shrinkage test to check is it ok to proceed the fabric since shrinkage issue is another big problem for the garment if its not checked and adjusted by pattern team.

- after this shrinkage pass, we need to do machine test for the fabric in order to find good condition to work with. usually we need to ask the mechanic for this test and they will try to find out some adjustment with machine to find it. they will focus on the speed, temperature and fabric condition after seamtape applied

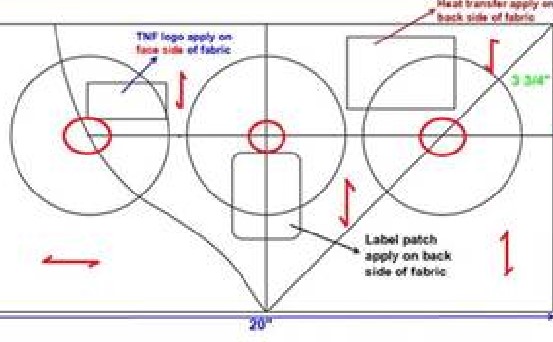

- when the condition is good to try, afterward we need to make mock up to see when its joined and seamtaped, it will not make a problem in the future, usually we make rectangle mock up as per below picture. Usually the critical join will applied on wavy panel i/o straight one for the seamtape, and also wider seamtape always use for critical points to cover the critical join.

4. when mock up is finished sewing by joining the panel and seamtaped by machine, we need to relax 24 hours before submit to lab in order to resting the temperature from heat

5. after submit lab test, the person in charge will do the suter first to check the fabric has any leakage issue or not, when its passed they will continue the process into washing 20x times to ensure seamtape doesnt peel off from the fabric. the mock up passed when the seamtape after suter and washing test has no peel off or leakage problem.

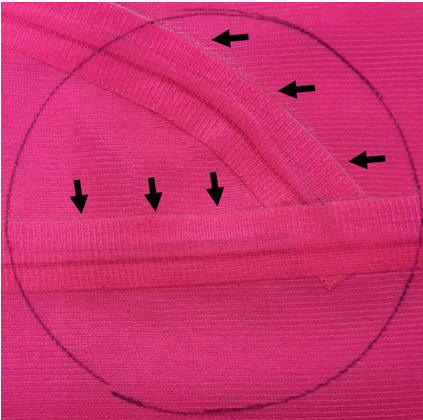

During sewing the seamtape and fab sometime has issue when applying. For example, usually new item has different issue than before. please kindly look picture below

the picture marked leakage position on fabric, it seems the fabric and seamtape is not suitable for waterproff garment. It can be other situation as condition not fit, workmanship when apply the seamtape, etc. We need to investigating more further regarding this kind of issue. If there is no clue of improvement, we need to inform supplier to check condition from 3rd party lab and do trial one more time by ourself. if its still not pass then we need to ask Buyer to change the seamtape item and fabric.